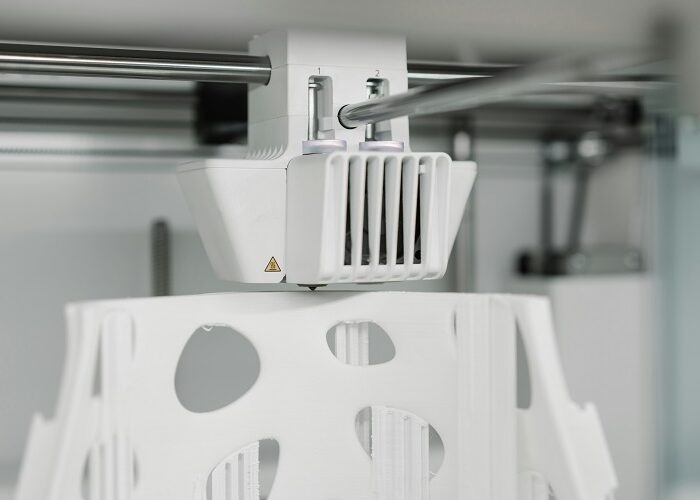

3D printing technology is evolving rapidly, transforming industries like manufacturing, healthcare, and product design. As we step into 2024 and beyond, the future of 3D printing holds exciting potential, offering innovative advancements that will redefine how we create, customize, and innovate.

Sustainable 3D Printing

Sustainability is becoming a key focus across industries, and 3D printing is no exception. The ability to create less waste through additive manufacturing is already a green solution. However, the future will see more eco-friendly materials, such as bio-based filaments and recycled plastics, which will reduce the environmental impact even further. Companies are prioritizing circular manufacturing systems, making 3D printing a cornerstone of sustainable practices.Multi-Material Printing

Traditional 3D printing typically uses a single material in each print job, but emerging technologies are enabling multi-material printing, allowing for the combination of different materials with varying properties in a single build. This trend is set to revolutionize sectors like healthcare, where intricate devices and prosthetics can be printed with both soft and hard materials, or in product design, where functionality and aesthetics are seamlessly integrated.Mass Customization

One of 3D printing’s most exciting potentials lies in mass customization. It allows businesses to produce personalized products at scale, whether it’s customized medical implants or bespoke consumer goods. In industries like fashion, footwear, and electronics, 3D printing offers consumers products tailored to their specific preferences, bridging the gap between mass production and individualized products.Advancements in Speed and Efficiency

Speed has always been a challenge for 3D printing, but new innovations are dramatically improving print times. In 2024, we can expect to see faster and more efficient printers that will bring 3D printing further into mainstream manufacturing. With reduced production times, companies will be able to produce large-scale items faster and more cost-effectively, opening the door for mass production in industries that previously viewed 3D printing as too slow.AI-Driven 3D Printing

Artificial intelligence is poised to enhance 3D printing by optimizing designs, improving material use, and automating much of the design and manufacturing process. AI can analyze complex data sets to improve the efficiency of the printing process, reducing errors and enhancing the overall quality of the final product. This will be particularly beneficial in sectors like aerospace and automotive, where precision is key.3D Printing in Healthcare

The healthcare industry continues to benefit from advancements in 3D printing. Custom prosthetics, dental implants, and even bio-printed tissues are pushing the boundaries of medical science. In the near future, 3D printing may allow for the creation of functional organs, revolutionizing organ transplants. This technology will enable personalized medical solutions, improving patient outcomes and lowering healthcare costs.Hybrid Manufacturing Solutions

As 3D printing technology advances, we will see more integration with traditional manufacturing methods. Hybrid manufacturing, which combines additive and subtractive manufacturing, will allow for the creation of more complex parts with higher precision. This fusion of technologies will cater to industries requiring complex geometries, such as aerospace, automotive, and engineering.

Conclusion

The future of 3D printing is set to be transformative across multiple industries. With innovations in sustainability, speed, multi-material capabilities, and AI integration, 3D printing will reshape manufacturing, healthcare, product design, and beyond. As we move into 2024, businesses must stay ahead of these trends to capitalize on the unprecedented opportunities this technology offers.