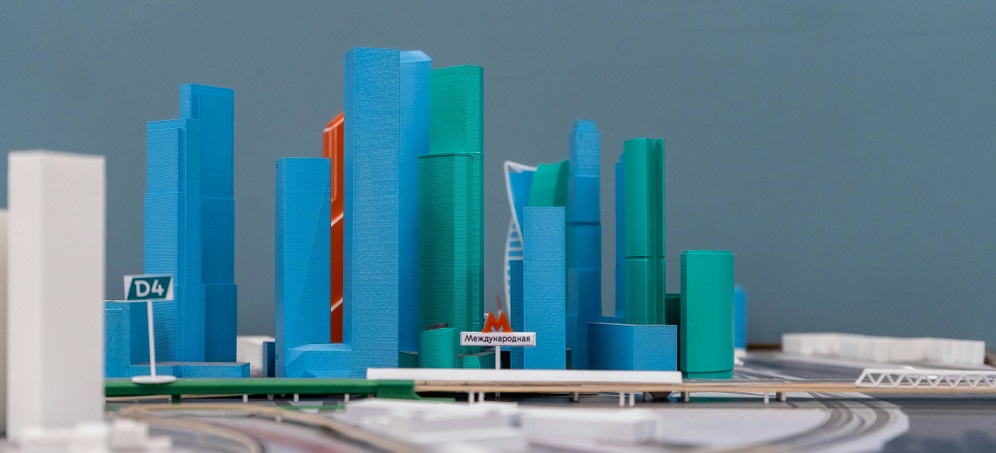

Resized models for Exhibitions & Expo.

3D printing has revolutionized the way models and prototypes are created, particularly for exhibitions and expos. This technology allows for the precise creation of scaled models, enabling designers, architects, engineers, and marketers to showcase their ideas in a tangible form. Here’s how 3D printing can be effectively used for resized models for exhibitions or expos:

Benefits of 3D Printing for Resized Models

Precision and Detail:

3D printing technology can capture intricate details and complex geometries that are often challenging to achieve with traditional methods. This ensures that scaled models accurately represent the full-sized versions.Customization:

Each model can be customized to specific requirements. Whether you need a smaller or larger version of a product, 3D printing can easily adjust the scale without losing detail or functionality.Cost-Effective:

Compared to traditional manufacturing techniques, 3D printing can be more cost-effective, especially for low-volume or one-off productions. It reduces material waste and eliminates the need for expensive molds or tooling.Speed:

The production time for 3D-printed models is significantly shorter. This allows for rapid prototyping and quick iterations, which is particularly useful in the fast-paced environment of exhibitions and expos.Material Variety:

3D printers can use a wide range of materials, including plastics, resins, metals, and even composites. This versatility allows for the creation of models that not only look realistic but also have the appropriate weight and feel.

Steps to Create Resized Models with 3D Printing

Design and Scaling:

Start with a digital 3D model created using CAD software. This model can be scaled to the desired size using the software, ensuring that all proportions remain accurate.Choosing the Right Material:

Select the appropriate material for the model based on the desired appearance and durability. For exhibition models, materials like PLA, ABS, or resin are commonly used due to their ease of printing and finishing.Printing the Model:

Use a high-quality 3D printer to produce the model. Ensure that the printer settings are optimized for the chosen material and the level of detail required. Layer height, print speed, and infill density are critical parameters to consider.Post-Processing:

Once printed, models often require post-processing to achieve the best finish. This can include sanding, painting, assembling multiple parts, and adding any additional details. Post-processing enhances the model’s aesthetics, making it more suitable for display.Presentation:

Prepare the model for the exhibition by mounting it on a base or incorporating it into a larger display. Consider lighting and placement to ensure the model attracts attention and communicates its intended message effectively.

Applications in Different Industries

Architecture:

Scaled-down models of buildings and urban layouts can be displayed to show potential clients or stakeholders.Engineering:

Functional prototypes of machines or parts can be demonstrated to illustrate their mechanics and operation.Consumer Products:

Scaled models of products like electronics, household items, or vehicles can be shown to highlight features and designs.Medical Field:

Anatomical models or medical devices can be exhibited for educational purposes or to showcase innovations.