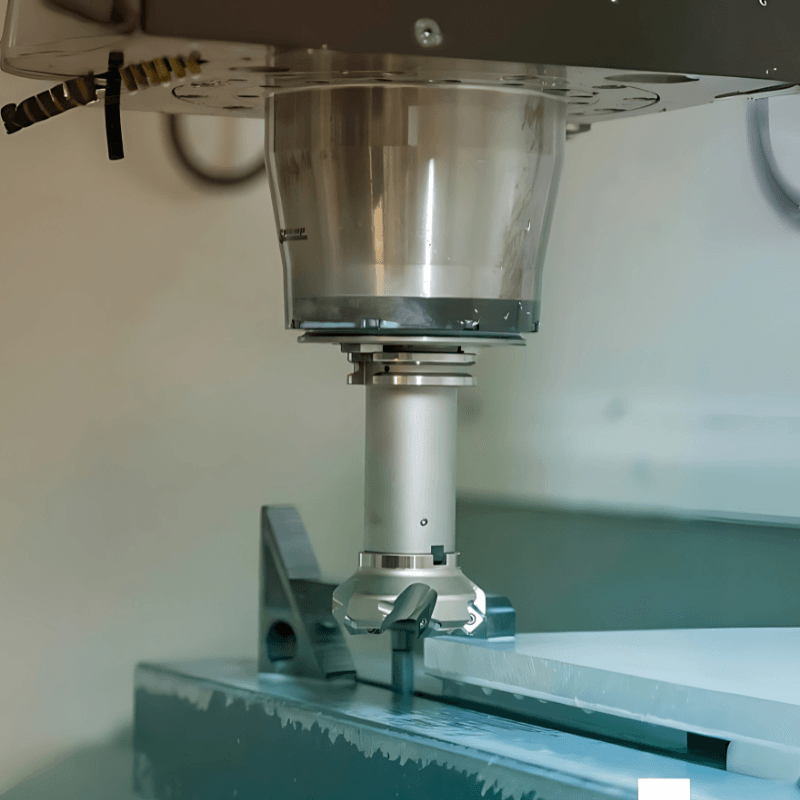

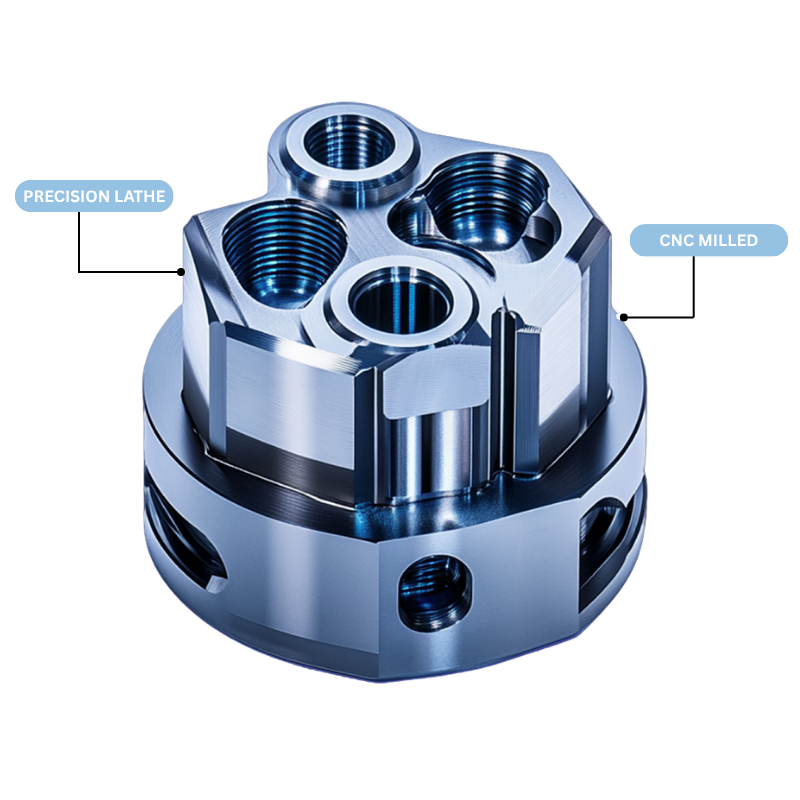

- CNC Milling: 3-Axis, 4-Axis, and 5-Axis Precision

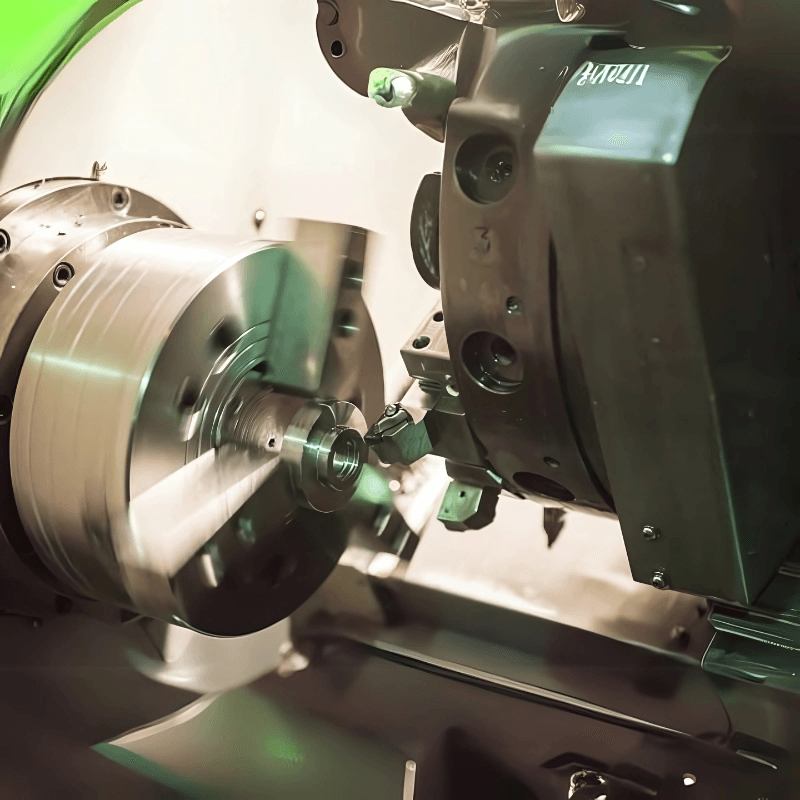

- CNC Turning and Lathe Services (2-Axis)

- CNC EDM: Wire EDM and EDM Hole Drilling for Intricate Cuts

- Standard QC, accuracy, mass manufacturing, minimum lead time, fast delivery, 100% support.

CNC Machining Services

Our Advanced CNC Machining Processes: Turning, Milling, and EDM

Get custom CNC parts machined in Aluminum, Steel, & Plastics. AddLayers offers high-precision CNC Turning, Milling (3- to 5-axis), and EDM with fast global delivery. Request a quote!

Services

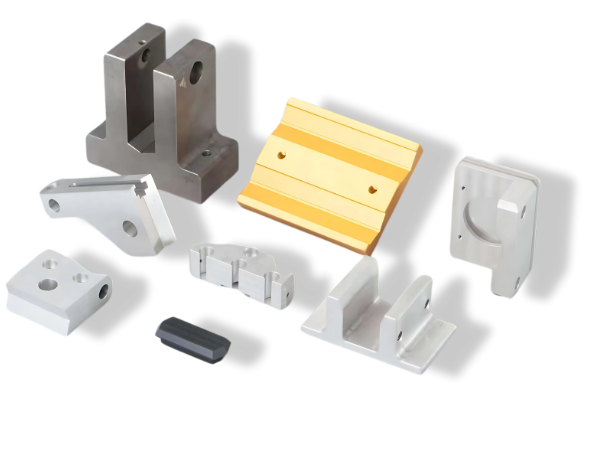

CNC Machining Solutions & Multi-Material

At AddLayers, we deliver world-class precision CNC Machining services specializing in CNC Turning, CNC Milling, and CNC-EDM (Wire EDM & EDM Hole Drilling). Our advanced 2-axis CNC Lathe machines and 3-axis, 4-axis, and 5-axis Milling machines ensure precision manufacturing with tight tolerances and high accuracy. We work with a wide range of production-grade materials, including Aluminum, Steel, Plastics/Polymers, Wood, and MDF, enabling us to cater to diverse industry needs from prototyping to mass production. Every part undergoes a strict Standard QC process to maintain top-quality standards. Choose us for reliable, efficient, and scalable CNC Machining solutions tailored to your requirements.

CNC Machining services specializing

At AddLayers, we specializing in CNC Turning, CNC Milling, CNC lathe, CNC-EDM & CNC Wood. Our advanced 2-axis CNC Lathe machines and 3-axis, 4-axis, and 5-axis Milling machines ensure precision manufacturing with standard tolerances and high accuracy. We work with a wide range of materials including Aluminum, Steel, Plastics/Polymers, Wood, and MDF, enabling us to cater to diverse industry needs.

CNC Machining Materials

We specialize in CNC machining with a wide range of materials including Aluminum, Steel, Stainless Steel, Copper, Brass, Bronze, and high-performance Plastics/Polymers, delivering precision and quality for every industrial application.

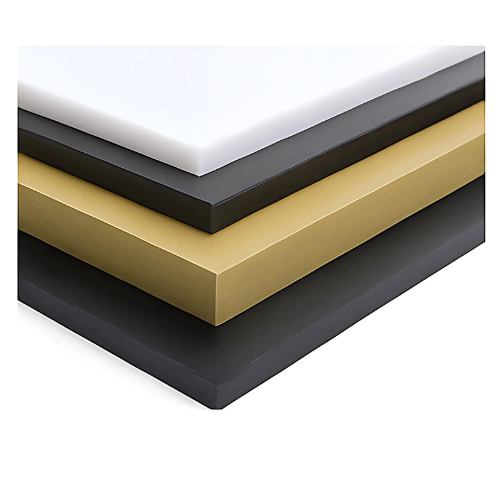

Engineering-Grade CNC Plastics/Polymers (ABS, PEEK, Delrin, etc.)

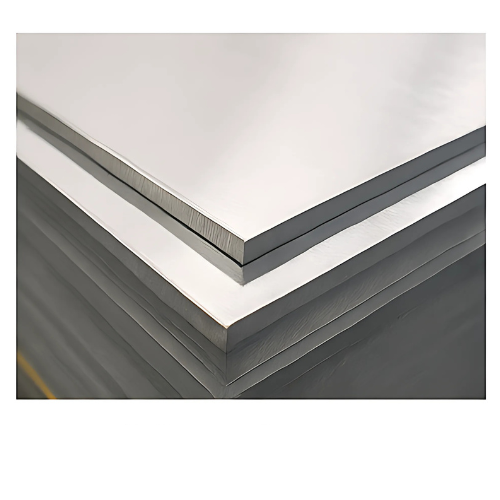

Aluminum

AL-6061, AL-7075, AL-5052

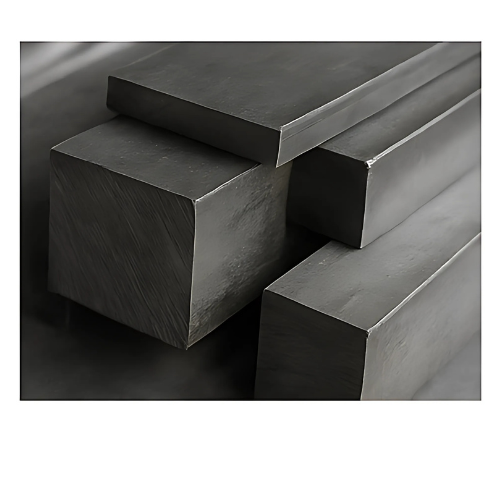

Steel

1020, 1045 (Carbon); 4140, 4150 (Alloy); C60, C80, HC14 (High Carbon); 42CrMo4

Stainless Steel

SS-304, SS-316, SS-420

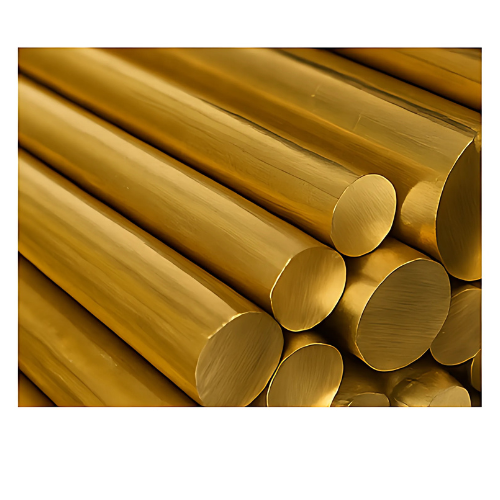

Copper, Brass, Bronze

C106 (Copper), MS58 (Brass), AL-Bronze & Tin-Bronze

Plastics/Polymers

ABS, Nylon PA-6, Polycarbonate (PC), PEEK, POM/Delrin/Acetal

Why AddLayers is Your Trusted Partner for Custom CNC Parts

At AddLayers, we deliver precision-driven 3D printing with cutting-edge technology, diverse materials, and tailored solutions for every industry. Our customer-centric, sustainable approach ensures high-quality, cost-effective results with fast turnaround times. 🚀

CNC machining uses computer-controlled tools to cut and shape materials into precise custom parts from digital designs.

Key types: CNC Milling (3-5 axis), CNC Turning (lathe), and CNC-EDM for intricate shapes and fine detail.

Common materials: Aluminum, Steel, Plastics, Wood, MDF. Nearly any solid material can be CNC machined.

Typical tolerance is ±0.005 in. High-precision machining can reach ±0.002 in or tighter for critical parts.

Lead times vary but usually range from 5 days to 2 weeks for prototypes; longer for complex or bulk jobs.

Costs depend on part complexity, material, tolerance, finishing, and order quantity. Simpler parts cost less.

Send a 3D model or drawing with material, quantity, and tolerance details to get a quick and accurate quote.

Preferred formats are STEP (.stp) or IGES (.igs). Include drawings or notes for tolerances and finishes.

Free instant quote & Consultation

Get pricing, project lead times, and DFM feedback.

Our Process

Simple Process to Get your parts.

01

Upload CAD file.

Share the CAD file with us in .stp, .stl, .obj. format. If you don't have CAD files, you can share basic sketch or drawing.

02

Choose Material.

Our Engineering team will contact you & suggest most convenient way to produce the parts & models. wide range of materials available in plastic & metals.

03

Place the order.

Our team will provide you with the best costing based on selected material & process of manufacturing.

04

Get the parts.

Once order is finalized, our manufacturing team will start the production & complete within minimum timeframe & send to your door step.