On-demand 3D printing services for rapid prototyping and production.

FDM, SLA, SLS, MJF, DMLS, and PolyJet 3D printing technologies available.

Wide material selection including plastic, nylon, and metal for various applications.

From prototyping to fully functional parts, meeting diverse industry needs.

100% expert assistance from the Add-Layers team for seamless execution.

Quick processing with optimized workflows for faster turnaround.

Fast and reliable global delivery, ensuring timely shipping worldwide.

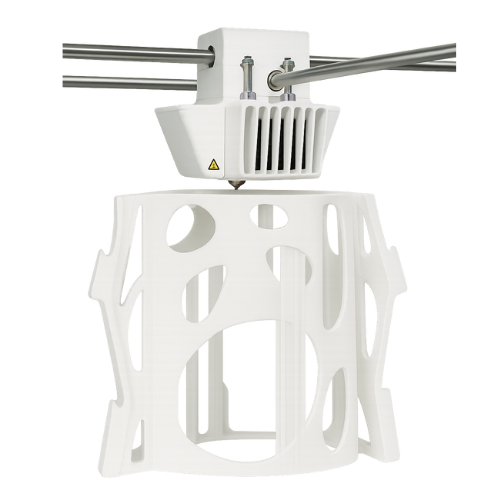

3d Printing Services

Our custom 3D printing services offer rapid prototyping and additive manufacturing solutions using advanced technologies like FDM, SLA, SLS, MJF, and SLM. We produce high-precision, durable components suitable for industries such as aerospace, automotive, and healthcare. Whether you need functional prototypes or production-ready parts, our services ensure accuracy and efficiency to meet your project requirements.

Services

Custom 3D Printing

Our custom 3D printing services offer rapid prototyping and additive manufacturing solutions using advanced technologies like FDM, SLA, SLS, MJF, and SLM. We produce high-precision, durable components suitable for industries such as aerospace, automotive, and healthcare. Whether you need functional prototypes or production-ready parts, our services ensure accuracy and efficiency to meet your project requirements. We specialize in producing functional prototypes and end-use parts tailored to the demands of aerospace, automotive, healthcare, and other advanced sectors. Our expertise in material selection and printing optimization allows us to manufacture lightweight, durable, and high-performance products. With a focus on speed and accuracy, we provide cost-effective solutions that bring your innovative ideas to life.

3D Printing processes

At AddLayers, we provide a comprehensive range of 3D printing materials to suit diverse applications, from rapid prototyping to high-performance production. Our advanced additive manufacturing technologies ensure precision, durability, and material versatility.

Comparison of different 3D printing processes.

Choosing the Right 3D Printing Process – A Detailed Comparison Selecting the best 3D printing technology depends on factors like surface finish, material strength, precision, and cost-effectiveness. Below is a detailed comparison of various 3D printing processes to help you make an informed decision based on your project needs.

| Material Name | Build Size | Surface finish | Layer Thickness | Min. wall thickness needed. | Lead time | Tolerances | Support Structure | Description |

|---|---|---|---|---|---|---|---|---|

| FDM | 300x300x450mm | Rough | 0.1-0.3mm | 0.7mm | 3 to 5 days | ±0.2 to ±3% | Required | Best & affordable for prototypes, with strong materials for special applications. |

| SLA | 800x800x1700mm | Smooth | 0.02mm | 0.5 to 0.7mm | 3 to 5 days | ±0.1% | Required | Best & affordable for prototypes with high accuracy & smooth finish. |

| SLS | 360x360x600mm | Slightly Rough | 0.1mm | 0.7mm | 3 to 5 days | ±0.2 | Not Required | The parts are highly durable & can be worked in actual working conditions. |

| MJF | 325x350x400mm | Grainy | 0.08mm | 0.7mm | 3 to 5 days | ±0.2% | Not Required | One of the most popular methods for industrial models & parts with high strength & toughness. |

| DMLS | 325x350x400mm | Slightly Rough | 0.02-0.08mm | 0.7 to 1mm | 5 to 7 days | ±0.2% | Required | For metal 3d printing DMLS is the only best option |

| Polyjet | 500x400x200mm | Smooth | 0.05mm | 0.8mm | 3 to 5 days | ±0.1% | Required | Various materials available, from flexible to tough, including medical & food-grade options. |

Advanced Surface Finishing & Post-Processing

Once a 3D-printed part is created, post-processing techniques enhance its appearance, durability, and functionality. At AddLayers.com, we specialize in professional finishing methods tailored for prototyping, industrial applications, and artistic models, ensuring every print meets high-quality standards.

Sanding

Starts with coarse grit, finishing with wet sanding for a polished, dust-free surface. Ensures smooth texture and refined details.

Chrome Plating

Chrome plating enhances the durability and aesthetic appeal of 3D prints, providing a smooth, reflective, and corrosion-resistant surface.

Painting

Primer boosts adhesion, followed by spray or acrylic paint, sealed with a clear coat for protection.

Polishing

Achieves a glossy finish via mechanical buffing or acetone vapor smoothing for select plastics.

Tumbling

Uses a rock tumbler and abrasive media to refine surfaces, ideal for smoothing small parts.

Why Choose Addlayers.com

At AddLayers, we deliver precision-driven 3D printing with cutting-edge technology, diverse materials, and tailored solutions for every industry. Our customer-centric, sustainable approach ensures high-quality, cost-effective results with fast turnaround times. 🚀

For basic prototypes, PLA (Polylactic Acid) is widely preferred due to its ease of printing, cost-effectiveness, and good surface finish. It's ideal for non-functional prototypes and concept model

ABS (Acrylonitrile Butadiene Styrene) offers higher strength and better heat resistance than PLA, making it suitable for functional parts. However, ABS can be more challenging to print due to its tendency to warp.

Nylon (e.g., FS3400PA) in Selective Laser Sintering (SLS) provides excellent mechanical properties, including durability and flexibility. It's ideal for functional prototypes and end-use parts.

Yes, TPU (Thermoplastic Polyurethane) is a flexible material known for its elasticity and abrasion resistance, making it ideal for parts like gaskets, seals, and wearable items.

Materials like ULTEM™ 1010 and High-Temperature Resin (SLA) are suitable for high-temperature applications due to their excellent thermal stability and strength.

Yes, ASA (Acrylonitrile Styrene Acrylate) is UV-stable and weather-resistant, making it ideal for outdoor applications where exposure to sunlight is a concern.

For transparent parts, materials like Transparent Resin (SLA) and Vero Clear (PolyJet) offer clarity and are used in applications requiring see-through components.

Materials such as ABS-M30I (FDM), ULTEM™ 1010 (FDM), and MED610 (PolyJet) are recognized for their biocompatibility and are suitable for medical and food-grade applications.

Free instant quote & Consultation

Get pricing, project lead times, and DFM feedback.

Our Process

Simple Process to Get your parts.

01

Upload CAD file.

Share the CAD file with us in .stp, .stl, .obj. format. If you don't have CAD files, you can share basic sketch or drawing.

02

Choose Material.

Our Engineering team will contact you & suggest most convenient way to produce the parts & models. wide range of materials available in plastic & metals.

03

Place the order.

Our team will provide you with the best costing based on selected material & process of manufacturing.

04

Get the parts.

Once order is finalized, our manufacturing team will start the production & complete within minimum timeframe & send to your door step.