Profile Cutting Services

At AddLayers, we provide high-accuracy Profile Cutting Services tailored to meet your design and production requirements. Whether you need simple 2D shapes or intricate profiles, our advanced equipment

Precision Profile Cutting Solutions

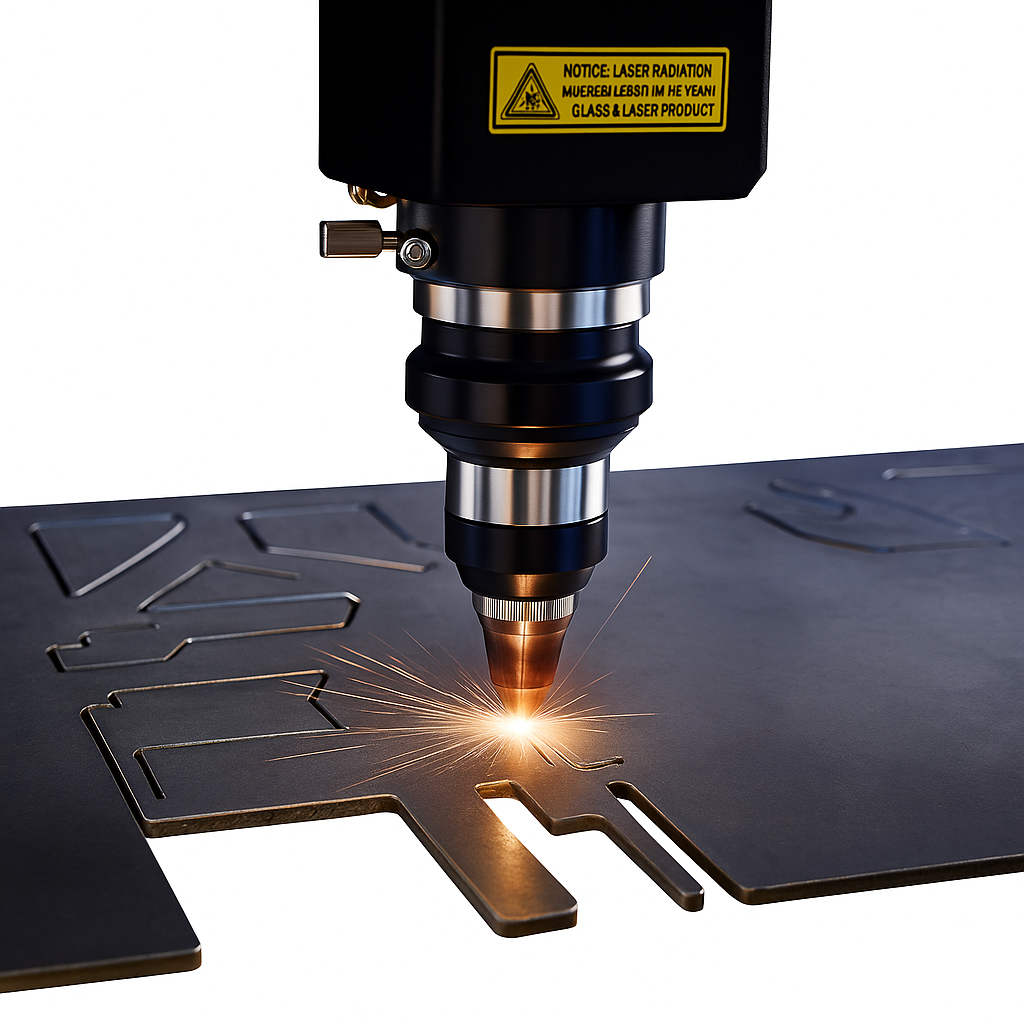

At AddLayers, we deliver high-quality Profile Cutting Services using the most advanced technologies in the industry — including Laser Cutting and Plasma Cutting. These methods allow us to handle a wide variety of materials and meet the demanding needs of precision manufacturing, prototyping, and industrial production.

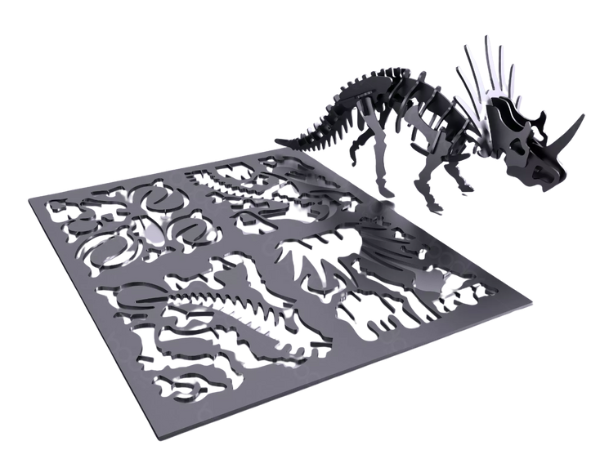

Our Profile Cutting capabilities cater to industries such as automotive, aerospace, architectural design, signage, interior manufacturing, heavy equipment, and custom fabrication. We specialize in producing accurate shapes and complex geometries on a range of materials like stainless steel, mild steel, aluminum, brass, acrylic, and MDF with high speed and consistency.

Laser & Plasma Profile Cutting

We use Laser Cutting for detailed, high-precision designs, especially on thinner materials or when a fine finish is required. For thicker materials and cost-effective large part production, we deploy Plasma Cutting, known for its fast cutting speeds and ability to work through conductive metals.

- Laser & Plasma Profile Cutting

- Precision-Cut Geometries in Metal

- Sheet Metal Profiling by Experts

- Custom Cut Solutions in Steel & More

Why Choose Addlayers.com

At AddLayers, we deliver precision-driven 3D printing with cutting-edge technology, diverse materials, and tailored solutions for every industry. Our customer-centric, sustainable approach ensures high-quality, cost-effective results with fast turnaround times. 🚀

Profile cutting is a precision fabrication process that uses advanced CNC-controlled laser cutting, plasma cutting, or waterjet cutting technologies to cut intricate shapes and patterns from sheet materials. This method is widely used in industrial manufacturing, metal fabrication, and custom prototyping due to its ability to deliver clean, accurate, and repeatable cuts for a variety of materials.

The most common profile cutting methods include laser cutting for high-precision and fine detailing, plasma cutting for fast and efficient cutting of conductive metals, and waterjet cutting for materials that are sensitive to heat. Each technique is chosen based on the material type, thickness, and required precision, making profile cutting highly adaptable for diverse industrial needs.

Profile cutting services support a wide range of materials including stainless steel, mild steel, aluminum, brass, acrylic, and MDF. Whether you're working with metals or non-metals, profile cutting ensures high-quality finishes and consistent results, making it suitable for industries like automotive, aerospace, signage, and interior design.

Profile cutting delivers excellent precision with typical tolerances ranging from ±0.1 mm for laser cutting to ±1 mm for plasma cutting, depending on the material and complexity. This high level of accuracy makes profile cutting ideal for applications that demand tight tolerances and detailed custom parts.

Lead times for profile cutting projects typically range from 1 to 4 business days, depending on the complexity, volume, and material used. With access to high-speed CNC machines, AddLayers ensures fast turnaround times and reliable delivery for urgent and large-scale production requirements.

The cost of profile cutting is influenced by several factors including material type and thickness, cutting method (laser or plasma), design complexity, part quantity, and any post-processing services like deburring or finishing. At AddLayers, we provide competitive pricing for high-precision profile cutting solutions.

To receive a fast and accurate quote for profile cutting services, simply upload your design files—preferably in DXF, DWG, or PDF format—along with specifications such as material, thickness, quantity, and delivery deadline. Our team at AddLayers will promptly review and provide a custom estimate.

For optimal results, we recommend submitting vector-based file formats such as DXF, DWG, AI, EPS, or high-resolution PDFs. These formats allow our CNC systems to interpret the design accurately and ensure precise laser or plasma profile cutting during production.

Free instant quote & Consultation

Get pricing, project lead times, and DFM feedback.

Our Process

Simple Process to Get your parts.

01

Upload CAD file.

Share the CAD file with us in .stp, .stl, .obj. format. If you don't have CAD files, you can share basic sketch or drawing.

02

Choose Material.

Our Engineering team will contact you & suggest most convenient way to produce the parts & models. wide range of materials available in plastic & metals.

03

Place the order.

Our team will provide you with the best costing based on selected material & process of manufacturing.

04

Get the parts.

Once order is finalized, our manufacturing team will start the production & complete within minimum timeframe & send to your door step.